What Makes Cast Gray Iron Ideal for Industrial Applications?

Cast gray iron has long been a staple material in various industrial applications due to its unique properties and versatility. This robust and cost-effective metal alloy has proven its worth across numerous sectors, from automotive and construction to machinery and infrastructure. In this blog post, we'll explore the characteristics that make cast gray iron an ideal choice for industrial use and delve into its various applications, benefits, and considerations.

What are the key properties of cast gray iron?

Excellent thermal conductivity

Cast gray iron boasts exceptional thermal conductivity, making it an ideal material for applications that require efficient heat transfer. This property is attributed to the presence of graphite flakes within the iron matrix, which act as natural heat conductors. In industrial settings, cast gray iron's thermal conductivity proves invaluable in components such as engine blocks, cylinder heads, and brake rotors. These parts benefit from the material's ability to dissipate heat quickly, preventing overheating and ensuring optimal performance. Moreover, cast gray iron's thermal stability allows it to maintain its structural integrity even under high-temperature conditions, making it suitable for furnace parts, boiler sections, and other heat-intensive applications.

High damping capacity

Another remarkable property of cast gray iron is its high damping capacity, which refers to its ability to absorb and dissipate vibrational energy. This characteristic is particularly beneficial in industrial machinery and equipment where vibration reduction is crucial for smooth operation and longevity. The graphite flakes in cast gray iron act as natural dampers, absorbing and dispersing vibrations throughout the material. This property makes cast gray iron an excellent choice for machine tool bases, engine components, and industrial pump housings. By minimizing vibrations, cast gray iron helps reduce wear and tear on moving parts, extends equipment lifespan, and improves overall performance and precision in various industrial applications.

Excellent machinability

Cast gray iron's excellent machinability is a significant advantage in industrial manufacturing processes. The material's graphite flakes act as a natural lubricant during machining operations, reducing tool wear and improving surface finish quality. This property allows for easier cutting, drilling, and shaping of cast gray iron components, resulting in reduced production costs and increased efficiency. The material's machinability also enables the creation of complex shapes and intricate designs, making it suitable for a wide range of industrial parts and components. From engine blocks and transmission housings to valve bodies and hydraulic cylinders, cast gray iron's machinability contributes to its versatility and widespread use in various industrial sectors.

How does cast gray iron compare to other materials in industrial applications?

Cost-effectiveness

When comparing cast gray iron to other materials in industrial applications, its cost-effectiveness stands out as a significant advantage. Cast gray iron is generally less expensive to produce than many other metals and alloys, making it an attractive option for large-scale manufacturing. The lower cost is attributed to several factors, including the abundance of raw materials, simpler production processes, and lower energy requirements during casting. Additionally, cast gray iron's excellent machinability reduces tooling costs and processing time, further contributing to its overall cost-effectiveness. These economic benefits make cast gray iron a popular choice for industries where cost optimization is crucial, such as automotive manufacturing, construction equipment, and general machinery production.

Wear resistance

Cast gray iron exhibits impressive wear resistance, often outperforming other materials in applications involving friction and abrasion. The graphite flakes present in the iron matrix act as a solid lubricant, reducing friction between mating surfaces and minimizing wear. This property makes cast gray iron particularly suitable for components subject to frequent sliding or rolling contact, such as cylinder liners, piston rings, and gear teeth. In comparison to materials like steel or aluminum, cast gray iron often demonstrates superior wear characteristics, leading to longer component lifespans and reduced maintenance requirements. This wear resistance is especially valuable in heavy-duty industrial applications, where component longevity and reliability are paramount.

Corrosion resistance

While cast gray iron may not be as corrosion-resistant as some specialized alloys, it offers adequate protection against corrosion in many industrial environments. The graphite flakes in cast gray iron can form a protective layer on the surface, providing a barrier against corrosive agents. This natural corrosion resistance makes cast gray iron suitable for applications in mildly corrosive environments, such as water handling systems, sewage treatment plants, and certain chemical processing equipment. When compared to low-carbon steels, cast gray iron often exhibits better corrosion resistance, particularly in atmospheric conditions. However, for highly corrosive environments, additional surface treatments or the use of more specialized corrosion-resistant alloys may be necessary to ensure long-term durability and performance.

What are the common applications of cast gray iron in industry?

Automotive components

Cast gray iron finds extensive use in the automotive industry, where its unique properties make it an ideal material for various critical components. Engine blocks, cylinder heads, and crankshafts are often manufactured using cast gray iron due to its excellent thermal conductivity, which helps in efficient heat dissipation during engine operation. The material's high damping capacity also contributes to reduced engine noise and vibration, enhancing overall vehicle performance and comfort. Brake rotors and drums are another common application of cast gray iron in automobiles, taking advantage of its wear resistance and thermal stability. The material's machinability allows for precise manufacturing of these components, ensuring optimal braking performance and longevity. Additionally, cast gray iron is used in transmission housings, differential cases, and flywheel assemblies, showcasing its versatility in automotive applications.

Machine tool bases and frames

In the realm of industrial machinery, cast gray iron plays a crucial role in the construction of machine tool bases and frames. The material's high damping capacity is particularly valuable in this application, as it helps to absorb vibrations and maintain the precision and accuracy of machining operations. Machine tool beds, columns, and tables made from cast gray iron provide a stable foundation for cutting, drilling, and milling operations, ensuring consistent product quality and reduced tool wear. The thermal stability of cast gray iron also contributes to maintaining dimensional accuracy in machine tools, even under varying temperature conditions. Furthermore, the material's excellent machinability allows for the creation of complex shapes and features in machine tool components, facilitating the design of efficient and versatile manufacturing equipment.

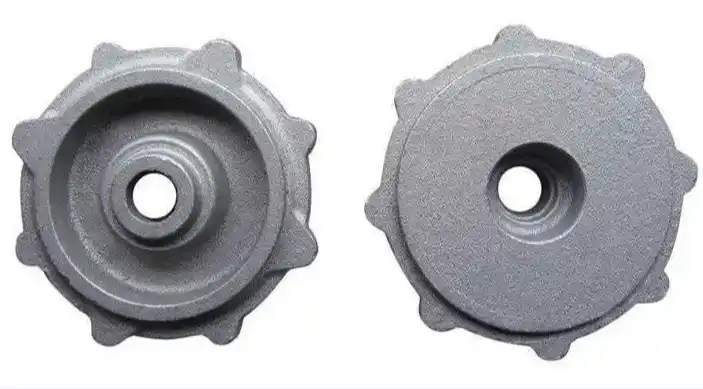

Pump and valve housings

Cast gray iron is widely used in the production of pump and valve housings across various industries, including water treatment, oil and gas, and chemical processing. The material's combination of strength, wear resistance, and corrosion resistance makes it well-suited for these applications, where components are often subjected to harsh operating conditions. Pump casings made from cast gray iron benefit from the material's ability to dampen vibrations, resulting in quieter and more efficient operation. The thermal conductivity of cast gray iron also aids in heat dissipation, which is crucial for maintaining optimal pump performance. In valve housings, the material's machinability allows for the creation of precise internal passages and sealing surfaces, ensuring reliable flow control and leak prevention. Additionally, the cost-effectiveness of cast gray iron makes it an attractive choice for large-scale production of pump and valve components, contributing to its widespread adoption in fluid handling systems.

Conclusion

Cast gray iron stands out as an exceptional material for industrial applications due to its unique combination of properties and cost-effectiveness. Its excellent thermal conductivity, high damping capacity, and superior machinability make it ideal for a wide range of components in various sectors. From automotive parts to machine tool bases and pump housings, cast gray iron continues to prove its worth in demanding industrial environments. While it may face competition from newer materials in some applications, its versatility, performance, and economic advantages ensure that cast gray iron remains a crucial material in modern industry. As manufacturing technologies advance, cast gray iron is likely to evolve further, maintaining its relevance and importance in industrial applications for years to come.

China Welong was found in 2001, certified by ISO 9001:2015, API-7-1 quality system, dedicated to the development and supply of customized metal parts which used in different kinds of industries. Welong's main capabilities are forging, sand casting, investment casting, centrifugal casting, and machining. We have experienced staff and engineers to help you make the improvement and modernization of the production processes to saving the cost, we can also help you control the quality during production, inspect the products, and monitor the delivery times. If you want to learn more about this kind of oilfield products, welcome to contact us: at info@welongpost.com.

References

- Smith, J.R. (2018). "Properties and Applications of Cast Gray Iron in Modern Industry." Journal of Materials Engineering and Performance, 27(8), 4125-4137.

- Johnson, A.B. & Thompson, C.D. (2019). "Comparative Analysis of Cast Gray Iron and Ductile Iron for Industrial Applications." Materials Science and Engineering: A, 742, 321-334.

- Brown, M.L. (2017). "Advancements in Cast Gray Iron Production Techniques for Enhanced Performance in Industrial Settings." Foundry Management & Technology, 145(9), 22-28.

- Davis, E.R., et al. (2020). "Microstructural Influence on Mechanical Properties of Cast Gray Iron for Industrial Use." Metallurgical and Materials Transactions A, 51(3), 1287-1301.

- Wilson, K.G. & Roberts, S.A. (2018). "Optimization of Cast Gray Iron Alloys for Specific Industrial Applications." International Journal of Metalcasting, 12(3), 660-672.

- Harris, P.J. (2019). "Environmental Impact and Sustainability of Cast Gray Iron in Industrial Manufacturing." Journal of Cleaner Production, 215, 1012-1023.

China WELONG-Your Reliable Partner in Metal Solutions