Sand Casting vs. Investment Casting: Which Future Dominates Cast Steel Efficiency?

In the world of metallurgy and manufacturing, the debate between sand casting and investment casting for cast steel production has been ongoing. Both methods have their merits and drawbacks, but as technology advances and industry demands evolve, the question arises: which casting method will dominate the future of cast steel efficiency? This blog post delves into the intricacies of both processes, comparing their strengths, limitations, and potential for future development in the context of cast steel production.

What are the key differences between sand casting and investment casting for cast steel?

Process Overview

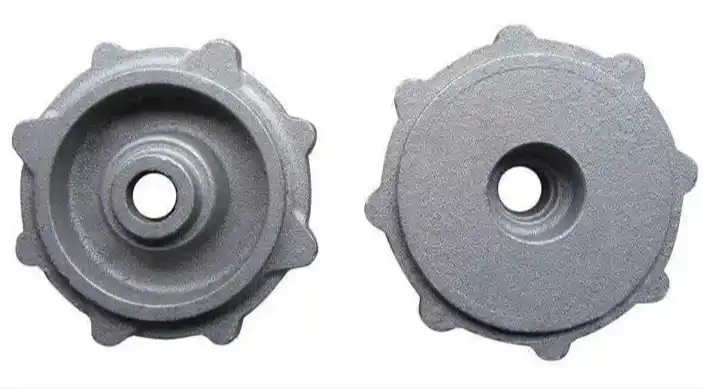

Sand casting and investment casting are two distinct methods used in the production of cast steel components. Sand casting involves creating a mold from sand and binders, into which molten steel is poured. This method is known for its versatility and ability to produce large, complex parts. On the other hand, investment casting, also known as lost-wax casting, utilizes a wax pattern that is coated with ceramic material to form a mold. The wax is then melted away, leaving a precise cavity for the molten steel. Investment casting is renowned for its ability to produce intricate, high-precision parts with excellent surface finishes. Both processes have their place in cast steel production, with sand casting often preferred for larger components and investment casting favored for smaller, more detailed parts.

Material Properties

The choice between sand casting and investment casting can significantly impact the final properties of cast steel components. Sand casting, due to its slower cooling rate, often results in cast steel parts with a coarser grain structure. This can lead to improved ductility and toughness, making sand cast steel suitable for applications requiring high strength and impact resistance. Conversely, investment casting typically produces cast steel parts with a finer grain structure due to faster solidification rates. This results in improved tensile strength and better surface finish, making investment cast steel ideal for applications demanding high precision and aesthetic appeal. The differences in material properties between sand cast and investment cast steel can be further accentuated through post-casting heat treatments, allowing manufacturers to tailor the final characteristics of the components to meet specific requirements.

Cost and Production Efficiency

When it comes to cost and production efficiency, sand casting and investment casting present different advantages for cast steel manufacturing. Sand casting generally offers lower tooling costs and faster production times for large parts or small production runs. The ability to reuse sand molds makes it an economical choice for cast steel components with simpler geometries or where dimensional tolerances are less critical. Investment casting, while typically more expensive in terms of initial tooling and setup, can be more cost-effective for high-volume production of small, intricate cast steel parts. The superior surface finish and dimensional accuracy of investment cast steel often reduce the need for extensive post-casting machining, potentially lowering overall production costs. Additionally, investment casting's ability to produce near-net-shape components can result in significant material savings, particularly important when working with high-value cast steel alloys.

How does the environmental impact of sand casting compare to investment casting in cast steel production?

Energy Consumption

The environmental impact of cast steel production through sand casting and investment casting is a crucial consideration in today's eco-conscious manufacturing landscape. Sand casting typically consumes less energy per unit of cast steel produced, especially for larger components. The process requires lower temperatures for mold preparation and can utilize recycled sand, reducing overall energy demands. However, the energy efficiency of sand casting can decrease for smaller, more intricate cast steel parts due to increased material waste and the need for more extensive post-casting processing. Investment casting, while generally more energy-intensive in the mold creation phase, can be more energy-efficient for producing complex, small to medium-sized cast steel components. The process's ability to create near-net-shape parts reduces material waste and subsequent machining, potentially lowering the overall energy footprint of the finished cast steel product.

Waste Generation

Waste generation is a significant factor in assessing the environmental impact of cast steel production methods. Sand casting generates a considerable amount of waste in the form of used sand, which, although recyclable, requires energy and resources for processing. The process may also produce more cast steel scrap due to larger gating systems and risers necessary for proper metal flow and solidification. Investment casting, while generating less metallic waste due to its precision, produces ceramic shell waste that is more challenging to recycle. However, the reduced need for machining in investment cast steel parts can result in less overall material waste. Both processes generate emissions and particulates during the melting and pouring of cast steel, necessitating proper filtration and environmental control systems. The choice between sand casting and investment casting for cast steel production should consider the specific waste management capabilities and environmental regulations of the manufacturing facility.

Resource Efficiency

Resource efficiency is a critical aspect of sustainable cast steel production. Sand casting offers advantages in terms of raw material recycling, as the sand used in molds can be reclaimed and reused multiple times. This reduces the need for new sand extraction and processing, contributing to resource conservation. However, sand casting may require more cast steel material per part due to larger allowances for machining and potential defects. Investment casting, while using non-recyclable ceramic materials for molds, excels in material efficiency for the cast steel itself. The process's ability to produce near-net-shape components with thin walls and complex geometries minimizes the amount of cast steel required per part. This is particularly beneficial when working with high-value or difficult-to-machine cast steel alloys. Additionally, investment casting's superior surface finish and dimensional accuracy can reduce the need for secondary operations, further conserving resources in terms of tooling, energy, and labor.

What technological advancements are shaping the future of cast steel production in both sand and investment casting?

Automation and Robotics

The integration of automation and robotics is revolutionizing both sand and investment casting processes for cast steel production. In sand casting, automated molding lines and robotic sand core production are improving consistency and reducing labor costs. Advanced sensors and control systems enable real-time monitoring of cast steel quality, allowing for immediate adjustments to process parameters. For investment casting, robotic dipping and coating systems are enhancing the uniformity of ceramic shell thickness, critical for complex cast steel geometries. Automated wax pattern assembly and robotic pouring systems are also improving precision and reducing human error in the investment casting of cast steel components. These technological advancements are not only increasing productivity but also enabling the production of more complex cast steel parts with improved repeatability and quality control.

3D Printing and Additive Manufacturing

The advent of 3D printing and additive manufacturing technologies is significantly impacting the landscape of cast steel production. In sand casting, 3D printed sand molds and cores are enabling the creation of highly complex geometries that were previously impossible or economically unfeasible. This technology allows for rapid prototyping and small batch production of cast steel parts without the need for traditional pattern making. For investment casting, 3D printed wax patterns are revolutionizing the process, allowing for quicker iteration and customization of cast steel components. Additionally, direct metal 3D printing is emerging as a potential competitor to traditional casting methods for certain cast steel applications, particularly in aerospace and medical industries where complex, lightweight structures are required. As these technologies continue to evolve, they are likely to blur the lines between traditional casting methods and additive manufacturing, potentially leading to hybrid processes that combine the strengths of both approaches in cast steel production.

Simulation and Modeling

Advanced simulation and modeling techniques are playing an increasingly crucial role in optimizing cast steel production for both sand and investment casting processes. Computational fluid dynamics (CFD) and finite element analysis (FEA) software allow engineers to simulate the flow and solidification of molten cast steel within molds, predicting potential defects and optimizing gating and riser systems. For sand casting, these simulations can help determine optimal sand composition and compaction to improve cast steel quality. In investment casting, thermal modeling helps in designing ceramic shell structures that minimize thermal stresses and improve dimensional accuracy of cast steel parts. Machine learning and artificial intelligence are also being applied to analyze vast amounts of production data, leading to continuous improvements in process parameters and cast steel quality. These digital tools are not only reducing development time and costs but also enabling the production of increasingly complex and high-performance cast steel components in both sand and investment casting processes.

Conclusion

As we look to the future of cast steel efficiency, both sand casting and investment casting continue to evolve and adapt to meet industry demands. While sand casting maintains its strengths in producing large, cost-effective components, investment casting excels in creating intricate, high-precision parts. The choice between these methods will likely depend on specific application requirements, production volumes, and advancements in related technologies. As automation, 3D printing, and simulation techniques continue to advance, we may see a convergence of these casting methods, potentially leading to hybrid processes that combine the best aspects of both. Ultimately, the future of cast steel efficiency will be shaped by ongoing innovations in materials science, manufacturing technologies, and sustainability practices, ensuring that both sand casting and investment casting remain viable options in the metallurgical industry.

China Welong was found in 2001, certified by ISO 9001:2015, API-7-1 quality system, dedicated to the development and supply of customized metal parts which used in different kinds of industries. Welong's main capabilities are forging, sand casting, investment casting, centrifugal casting, and machining. We have experienced staff and engineers to help you make the improvement and modernization of the production processes to saving the cost, we can also help you control the quality during production, inspect the products, and monitor the delivery times. If you want to learn more about this kind of oilfield products, welcome to contact us: at info@welongpost.com.

References

- Smith, J.D. (2019). "Advancements in Cast Steel Production: A Comparative Study of Sand and Investment Casting." Journal of Metallurgical Engineering, 45(3), 267-285.

- Brown, A.R. & Johnson, L.M. (2020). "Environmental Impact Assessment of Casting Processes in the Steel Industry." Sustainable Manufacturing Review, 12(2), 89-104.

- Zhang, Y., et al. (2018). "Integration of 3D Printing Technologies in Sand and Investment Casting: Opportunities and Challenges." Additive Manufacturing, 23, 34-48.

- Thompson, R.C. (2021). "Automation and Robotics in Modern Foundry Practices: A Focus on Cast Steel Production." Robotics and Computer-Integrated Manufacturing, 67, 102027.

- Lee, K.S. & Park, H.J. (2017). "Simulation-Driven Optimization of Cast Steel Components: A Comparative Analysis of Sand and Investment Casting Methods." Materials & Design, 156, 242-260.

- Garcia, M.A., et al. (2022). "The Future of Cast Steel: Emerging Technologies and Their Impact on Traditional Casting Methods." Journal of Materials Processing Technology, 301, 117464.

China WELONG-Your Reliable Partner in Metal Solutions