The Role of Stabilizer Rolls in Printing Machines

Tension Control and Web Stability

One of the primary functions of stabilizer rolls is to maintain proper tension control throughout the printing process. These rolls are strategically positioned within the machine to guide the paper or substrate, ensuring it remains taut and flat as it moves through various printing stages. By maintaining consistent tension, stabilizer rolls help prevent issues such as web flutter, which can cause misalignment and poor print quality. The rolls' precision-engineered surface and balanced construction contribute to smooth rotation, minimizing vibration and enhancing overall stability.

Wrinkle Prevention and Flatness Maintenance

Wrinkles and creases in the substrate can severely impact print quality and lead to wastage. Stabilizer rolls are designed to help prevent these issues by maintaining the flatness of the material as it passes through the printing machine. The rolls' carefully calculated geometry and surface finish work together to spread the substrate evenly, eliminating potential wrinkles before they can form. This not only improves print quality but also reduces the likelihood of paper jams and other disruptions to the printing process.

Uniform Ink Transfer and Print Consistency

The stability provided by these rolls is essential for achieving uniform ink transfer across the substrate. By keeping the paper or film perfectly aligned and tensioned, stabilizer rolls ensure that the printing plates or cylinders make consistent contact with the surface. This results in more even ink distribution, sharper images, and improved color consistency throughout the print run. The enhanced print quality achieved through the use of stabilizer rolls can significantly impact customer satisfaction and reduce the need for reprints or adjustments.

Advancements in Stabilizer Roll Technology

Materials and Coatings

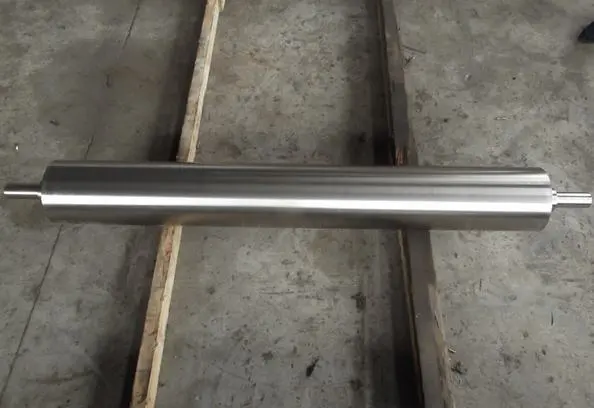

Recent advancements in materials science have led to the development of high-performance stabilizer rolls that offer improved durability and functionality. Modern rolls often feature specialized coatings or surface treatments that enhance their ability to grip and guide the substrate without causing damage. These coatings can also improve wear resistance, extending the lifespan of the rolls and reducing maintenance requirements. Some manufacturers now offer stabilizer rolls made from advanced composite materials, which provide excellent dimensional stability and reduced weight compared to traditional metal rolls.

Precision Manufacturing Techniques

The manufacturing processes used to produce stabilizer rolls have become increasingly sophisticated, resulting in components with tighter tolerances and improved performance characteristics. Computer-controlled machining and grinding techniques allow for the creation of rolls with extremely precise dimensions and surface finishes. This level of accuracy is crucial for maintaining consistent tension and alignment across the entire width of the substrate, even at high production speeds. Additionally, advanced balancing techniques ensure that the rolls operate smoothly, minimizing vibration and potential disruptions to the printing process.

Integration of Sensors and Control Systems

Modern stabilizer rolls are often equipped with integrated sensors and control systems that allow for real-time monitoring and adjustment of tension and alignment. These smart rolls can detect variations in substrate properties or printing conditions and automatically make minute adjustments to maintain optimal performance. By incorporating such advanced technologies, printing machine operators can achieve greater consistency and reduce the need for manual interventions during production runs. This level of automation not only improves print quality but also contributes to increased efficiency and reduced waste.

Optimizing Printing Machine Performance with Stabilizer Rolls

Proper Selection and Sizing

Selecting the right stabilizer rolls for a specific printing application is crucial for achieving optimal performance. Factors such as substrate type, printing speed, and machine configuration must be carefully considered when choosing rolls. The diameter, length, and surface characteristics of the rolls should be tailored to the specific requirements of the printing process. Consulting with experienced manufacturers or engineers can help ensure that the selected stabilizer rolls are properly sized and specified for maximum effectiveness.

Installation and Alignment

Proper installation and alignment of stabilizer rolls are essential for realizing their full potential in optimizing printing machine performance. The rolls must be positioned correctly within the machine to provide the right amount of tension and guidance to the substrate. Precise alignment ensures that the rolls work in harmony with other components, such as idler rollers and printing cylinders. Regular inspection and adjustment of roll alignment can help maintain optimal performance and prevent issues such as uneven wear or misregistration.

Maintenance and Monitoring

To ensure continued optimal performance, stabilizer rolls require regular maintenance and monitoring. This includes periodic cleaning to remove ink, paper dust, and other contaminants that can accumulate on the roll surface. Inspection of roll bearings and shaft alignment should be carried out at regular intervals to detect and address any potential issues before they impact print quality. Additionally, implementing a proactive maintenance schedule can help extend the lifespan of stabilizer rolls and minimize unexpected downtime.

In conclusion, stabilizer rolls are indispensable components in modern printing machines, playing a vital role in optimizing performance and print quality. By carefully selecting, installing, and maintaining these precision-engineered rolls, printing operations can achieve higher levels of efficiency, consistency, and customer satisfaction. As technology continues to advance, we can expect to see further improvements in stabilizer roll design and functionality, leading to even greater enhancements in printing machine performance. For more information about stabilizer rolls and their applications in various industries, please contact us at info@welongpost.com.