Design and Materials of Furnace Rolls

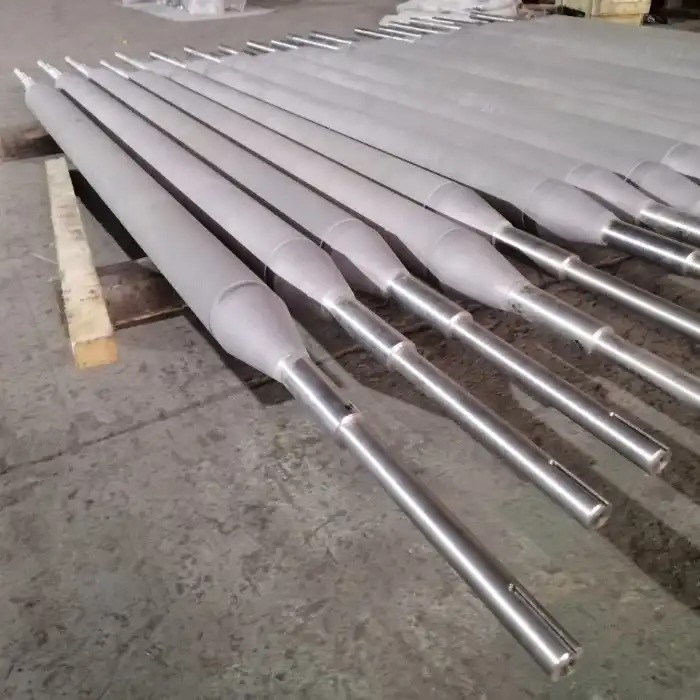

Heat-Resistant Alloys

The foundation of any high-performance furnace roll lies in its material composition. Advanced heat-resistant alloys, such as nickel-chromium-based superalloys or iron-chromium-aluminum alloys, form the core of these critical components. These materials are meticulously selected for their ability to maintain strength, resist oxidation, and prevent creep at elevated temperatures. The incorporation of elements like molybdenum, tungsten, and cobalt further enhances the alloy's high-temperature stability and mechanical properties.

Surface Coatings and Treatments

To augment the inherent properties of the base alloy, furnace rolls often undergo sophisticated surface treatments. Thermal spray coatings, such as ceramic or cermet layers, can be applied to improve wear resistance and thermal insulation. Some rolls may feature diffusion aluminide coatings, which form a protective aluminum oxide layer, significantly enhancing oxidation resistance. These surface modifications not only extend the operational life of the rolls but also prevent contamination of the processed materials.

Structural Design Considerations

The structural design of furnace rolls is equally crucial to their performance. Engineers must consider factors such as thermal expansion, load-bearing capacity, and rotational stability. Hollow designs with internal cooling systems are often employed to manage thermal gradients and prevent distortion. The roll's surface may incorporate specific patterns or textures to optimize material handling and heat transfer characteristics. Every aspect of the roll's geometry is carefully calculated to ensure optimal performance under extreme conditions.

Operational Advantages of Furnace Rolls

Enhanced Process Efficiency

Furnace rolls significantly boost process efficiency in high-temperature operations. By enabling continuous material movement through the furnace, they eliminate the need for batch processing, leading to increased throughput and reduced energy consumption. The rolls' ability to maintain consistent contact with the processed material ensures uniform heat distribution, minimizing temperature fluctuations that could compromise product quality. This efficiency translates into shorter processing times, lower operational costs, and improved overall productivity for manufacturers.

Improved Product Quality

The use of high-quality furnace rolls directly impacts the end product's quality. By providing a stable and controlled environment for material transport, these rolls help prevent defects such as warping, uneven heating, or surface imperfections. The precise control over material handling allows for more accurate temperature profiles and cooling rates, crucial for achieving desired material properties in processes like steel annealing or glass tempering. The result is consistently high-quality products that meet stringent industry standards and customer expectations.

Longevity and Maintenance Benefits

Well-designed furnace rolls offer substantial longevity and maintenance advantages. Their robust construction and advanced materials resist wear, corrosion, and thermal fatigue, extending operational life and reducing the frequency of replacements. This durability translates into less downtime for maintenance and repairs, ensuring continuous production cycles. Additionally, the superior performance of these rolls often results in reduced energy consumption and lower overall operational costs, making them a cost-effective solution for high-temperature processing facilities.

Applications and Industry Impact

Metallurgical Processing

In the metallurgical industry, furnace rolls are indispensable for processes such as continuous annealing, galvanizing, and heat treatment of steel and aluminum products. These rolls enable the precise control of temperature and material flow necessary for achieving specific material properties. For instance, in continuous annealing lines, furnace rolls support the steel strip as it passes through various heating and cooling zones, ensuring uniform treatment and optimal mechanical properties. The rolls' ability to withstand high temperatures and corrosive environments makes them crucial for producing high-quality metal products with consistent characteristics.

Glass Manufacturing

The glass industry relies heavily on furnace rolls for the production of float glass, tempered glass, and specialty glass products. In float glass production, these rolls support the molten glass as it flows over a bath of molten tin, ensuring a perfectly flat and smooth surface. During the tempering process, furnace rolls facilitate the rapid and uniform heating and cooling of glass sheets, imparting the necessary stress patterns for increased strength and safety. The precision and reliability of these rolls are critical for maintaining the optical quality and structural integrity of glass products used in construction, automotive, and electronics industries.

Advanced Materials and Emerging Technologies

As industries evolve, furnace rolls are finding new applications in the production of advanced materials and emerging technologies. In the manufacturing of carbon fiber composites, these rolls play a vital role in the oxidation and carbonization stages, where precise temperature control is crucial. The semiconductor industry utilizes specialized furnace rolls in processes like silicon wafer annealing and thin film deposition. Additionally, the development of next-generation battery technologies and solar panel materials often involves high-temperature processes where furnace rolls are essential for ensuring product quality and process efficiency.

In conclusion, furnace rolls are indispensable components in high-temperature processing across a wide range of industries. Their sophisticated design, incorporating advanced materials and surface treatments, enables them to withstand extreme conditions while providing crucial operational benefits. From enhancing process efficiency and product quality to offering long-term cost savings, these specialized components continue to play a pivotal role in modern manufacturing. As industries push the boundaries of material science and processing technologies, the importance of high-performance furnace rolls is only set to increase. For more information on custom furnace rolls and high-temperature processing solutions, please contact us at info@welongpost.com.