Thermal Fatigue and Its Impact on Furnace Rolls

Understanding Thermal Fatigue in Furnace Rolls

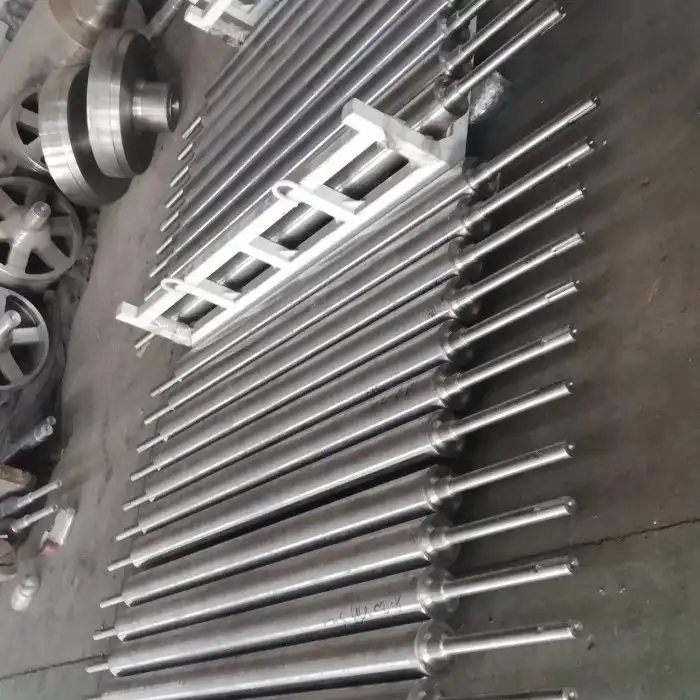

Thermal fatigue is a significant challenge faced by furnace rolls. It occurs due to the repeated heating and cooling cycles that these components undergo during operation. As the furnace heats up and cools down, the roll material expands and contracts, leading to thermal stresses. Over time, these cyclic stresses can cause microscopic cracks to form and propagate, ultimately leading to material failure.

Consequences of Thermal Fatigue on Roll Performance

The effects of thermal fatigue on furnace rolls can be severe. As cracks develop, the roll's surface integrity is compromised, leading to uneven heat distribution and potential product defects. In extreme cases, thermal fatigue can cause catastrophic failure, resulting in costly downtime and safety hazards. The reduced lifespan of furnace rolls due to thermal fatigue also increases maintenance and replacement costs for industrial operations.

Mitigating Thermal Fatigue in Furnace Rolls

To address thermal fatigue, manufacturers employ various strategies. Advanced materials with improved thermal shock resistance, such as high-temperature alloys or ceramic composites, are increasingly used in furnace roll production. Innovative cooling systems and thermal barrier coatings can help manage temperature gradients and reduce thermal stresses. Additionally, optimizing furnace operation parameters and implementing proper heating and cooling procedures can significantly extend the life of furnace rolls by minimizing thermal fatigue effects.

Oxidation and Corrosion Resistance in Furnace Rolls

The Oxidation Challenge in High-Temperature Environments

Oxidation poses a significant challenge for furnace rolls operating in high-temperature environments. As temperatures rise, the rate of oxidation increases exponentially, leading to rapid material degradation. This process forms oxide scales on the roll surface, which can flake off and cause surface irregularities. The loss of material due to oxidation not only affects the dimensional accuracy of the rolls but also compromises their structural integrity over time.

Corrosive Atmospheres and Their Effects on Furnace Rolls

In addition to oxidation, furnace rolls often face corrosive atmospheres in industrial settings. These atmospheres may contain sulfur, chlorine, or other corrosive elements that accelerate material degradation. The combination of high temperatures and corrosive gases can lead to aggressive chemical attacks on the roll material, causing pitting, scaling, and eventual failure. This corrosion can significantly reduce the service life of furnace rolls and impact the quality of processed materials.

Strategies for Enhancing Oxidation and Corrosion Resistance

To combat oxidation and corrosion, manufacturers employ various techniques. The selection of advanced alloys with high chromium content or the addition of elements like aluminum or silicon can form protective oxide layers that resist further oxidation. Specialized coatings, such as thermal spray coatings or diffusion coatings, can provide an additional barrier against oxidation and corrosion. Regular maintenance, including cleaning and inspection, helps identify early signs of oxidation or corrosion, allowing for timely intervention and preventive measures.

Mechanical Wear and Surface Integrity of Furnace Rolls

Mechanisms of Mechanical Wear in Furnace Rolls

Mechanical wear is a persistent challenge for furnace rolls, particularly in applications involving direct contact with processed materials. The primary wear mechanisms include abrasion, erosion, and adhesion. Abrasive wear occurs when hard particles in the processed materials scratch or gouge the roll surface. Erosive wear results from the impact of particles or fluids on the roll surface, especially in high-velocity environments. Adhesive wear happens when there is metal-to-metal contact between the roll and other furnace components or processed materials, leading to material transfer and surface damage.

Impact of Wear on Surface Integrity and Performance

The consequences of mechanical wear on furnace rolls are significant. As the roll surface deteriorates, it can lead to uneven heat distribution, affecting the quality of processed materials. Worn surfaces may cause dimensional inaccuracies in the final product and increase the risk of material defects. Moreover, excessive wear can lead to premature roll failure, resulting in unscheduled downtime and increased maintenance costs. Maintaining surface integrity is crucial for ensuring consistent product quality and optimal furnace performance.

Advanced Solutions for Enhancing Wear Resistance

To combat mechanical wear, manufacturers are implementing various innovative solutions. The use of advanced materials with superior hardness and wear resistance, such as high-chromium alloys or ceramic composites, can significantly extend roll life. Surface treatments like nitriding, carburizing, or the application of hard-facing alloys can enhance the wear resistance of roll surfaces. Additionally, the development of engineered surface textures or patterns can help optimize lubrication and reduce friction, further mitigating wear. Regular monitoring and predictive maintenance techniques, such as vibration analysis or ultrasonic testing, can help identify wear patterns early and allow for timely interventions.

In conclusion, addressing the common challenges faced by furnace rolls requires a multifaceted approach. By understanding and mitigating issues related to thermal fatigue, oxidation, corrosion, and mechanical wear, manufacturers can significantly improve the performance and longevity of furnace rolls. This not only enhances operational efficiency but also reduces maintenance costs and improves product quality. For more information on furnace rolls and customized solutions for your specific industrial needs, please contact us at info@welongpost.com.