Material Composition and Thermal Properties

Alloy Selection for Optimal Performance

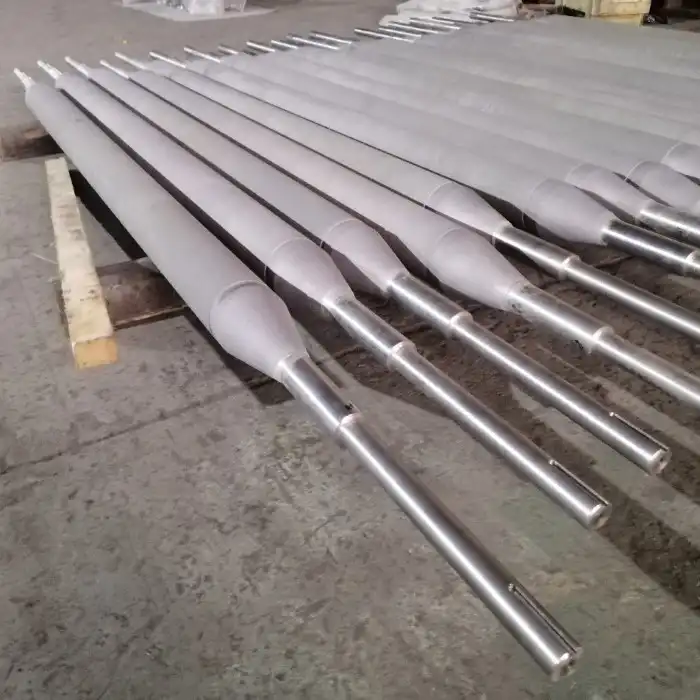

The choice of alloy significantly impacts a furnace roll's performance. High-temperature alloys, such as heat-resistant stainless steels or nickel-based superalloys, are often employed due to their superior thermal properties. These materials exhibit excellent resistance to oxidation and maintain their mechanical strength at elevated temperatures. The specific alloy composition can be tailored to meet the unique requirements of different furnace environments, balancing factors such as thermal conductivity, thermal expansion, and creep resistance.

Thermal Conductivity and Heat Distribution

Thermal conductivity is a critical KPI for furnace rolls, as it directly affects heat distribution and energy efficiency. Rolls with optimal thermal conductivity ensure uniform heat transfer to the processed materials, resulting in consistent product quality. Moreover, efficient heat distribution can lead to reduced energy consumption and improved overall furnace performance. Manufacturers often employ advanced materials or engineered structures to enhance the thermal conductivity of furnace rolls while maintaining other essential properties.

Coefficient of Thermal Expansion

The coefficient of thermal expansion (CTE) is another crucial factor in evaluating furnace roll performance. Materials with low and stable CTE are preferred to minimize dimensional changes during heating and cooling cycles. This property is particularly important for maintaining roll shape and preventing warping or distortion, which could lead to uneven processing or product defects. Careful consideration of the CTE helps ensure the longevity and reliability of furnace rolls in high-temperature applications.

Mechanical Durability and Wear Resistance

Hardness and Strength at Elevated Temperatures

The ability of furnace rolls to maintain their mechanical properties at high temperatures is a key performance indicator. Materials that exhibit high hot hardness and strength are essential for withstanding the demanding conditions inside industrial furnaces. These properties prevent deformation and ensure the rolls maintain their shape and function throughout their operational life. Advanced alloys and composite materials are often developed to provide superior mechanical performance under extreme thermal conditions.

Wear Resistance and Surface Integrity

Wear resistance is a critical factor in the longevity and performance of furnace rolls. Rolls that can withstand abrasion, erosion, and other forms of wear maintain their surface quality and dimensional accuracy over time. This characteristic is particularly important in applications where the rolls come into direct contact with processed materials or in environments with high particulate content. Surface treatments, coatings, or specialized alloy compositions are often employed to enhance wear resistance and extend the service life of furnace rolls.

Fatigue Resistance and Crack Propagation

The cyclic nature of many furnace operations subjects rolls to thermal and mechanical fatigue. Evaluating a roll's resistance to fatigue and its ability to prevent crack initiation and propagation is crucial for predicting its lifespan and reliability. Materials and designs that exhibit high fatigue resistance contribute to reduced maintenance requirements and improved operational continuity. Advanced non-destructive testing methods are often used to monitor the structural integrity of furnace rolls and detect potential fatigue-related issues before they lead to failure.

Corrosion Resistance and Environmental Factors

High-Temperature Oxidation Resistance

In the harsh environment of industrial furnaces, oxidation resistance is a paramount KPI for furnace rolls. The ability to withstand high-temperature oxidation prevents the formation of detrimental oxide scales that can compromise the roll's performance and lead to material loss. Alloys rich in chromium, aluminum, or silicon are often utilized to form protective oxide layers that inhibit further oxidation. The effectiveness of a roll's oxidation resistance directly impacts its service life and the quality of the processed materials.

Resistance to Chemical Attack

Furnace rolls may be exposed to various corrosive agents, depending on the specific industrial process. Resistance to chemical attack from molten metals, aggressive gases, or other corrosive substances is essential for maintaining the integrity of the rolls. This KPI is particularly critical in industries such as steel production or chemical processing, where the furnace atmosphere can be highly corrosive. The selection of materials with appropriate chemical resistance properties ensures the longevity and reliability of furnace rolls in these challenging environments.

Thermal Shock Resistance

The ability to withstand rapid temperature changes without cracking or spalling is a crucial performance indicator for furnace rolls. Thermal shock resistance is particularly important in processes involving intermittent heating and cooling cycles or where rolls may be exposed to sudden temperature fluctuations. Materials with low thermal expansion coefficients and high thermal conductivity tend to exhibit better thermal shock resistance. This property ensures that furnace rolls can maintain their structural integrity and performance even under severe thermal cycling conditions.

In conclusion, evaluating furnace rolls requires a comprehensive assessment of various Key Performance Indicators. From material composition and thermal properties to mechanical durability and corrosion resistance, each factor plays a vital role in determining the overall performance and longevity of furnace rolls. By carefully considering these KPIs, manufacturers can select or design furnace rolls that meet the specific demands of their industrial processes, ensuring optimal efficiency, product quality, and operational reliability. For more information on high-quality furnace rolls and custom metal parts for various industries, please contact us at info@welongpost.com.