The Importance of Furnace Rolls in Industrial Processes

Role of Furnace Rolls in Heat Treatment

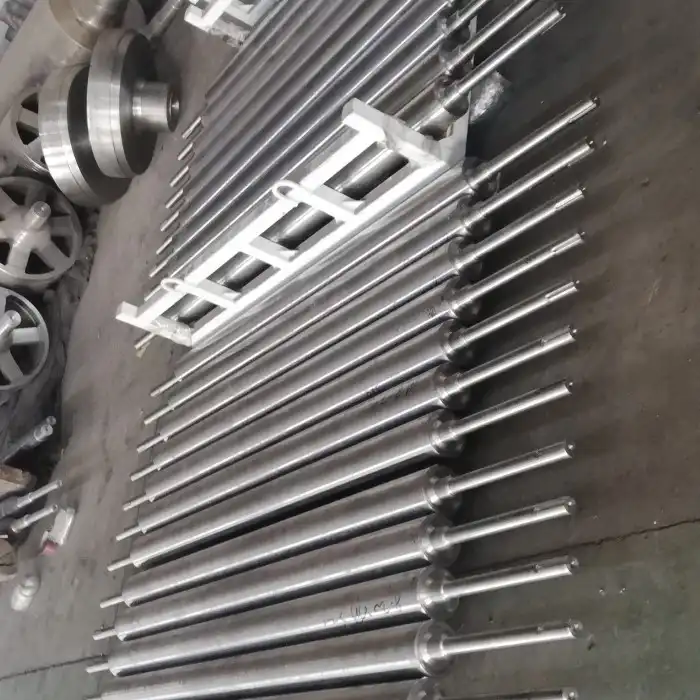

Furnace rolls serve as critical components in heat treatment processes, supporting and transporting materials through high-temperature environments. These specialized rolls are engineered to withstand extreme thermal conditions while maintaining their structural integrity and dimensional stability. In heat treatment applications, furnace rolls facilitate uniform heating of materials, ensuring consistent quality and properties throughout the treated products. The ability of furnace rolls to operate reliably in these demanding conditions is essential for maintaining continuous production and minimizing interruptions due to equipment failure or maintenance.

Material Considerations for Furnace Rolls

The selection of appropriate materials for furnace rolls is paramount to their performance and longevity. High-temperature alloys, such as heat-resistant stainless steels and nickel-based superalloys, are commonly used in the fabrication of furnace rolls. These materials exhibit exceptional resistance to thermal fatigue, oxidation, and creep at elevated temperatures. The choice of material depends on factors such as operating temperature, atmosphere, and the specific requirements of the application. Advanced materials and coatings can further enhance the durability and performance of furnace rolls, contributing to extended service life and reduced maintenance frequency.

Design Considerations for Optimal Performance

The design of furnace rolls plays a significant role in their ability to minimize downtime. Factors such as roll diameter, length, and surface finish are carefully considered to optimize performance and durability. Innovative design features, such as internal cooling systems and stress-relieving geometries, can enhance the thermal management and mechanical stability of furnace rolls. Additionally, the integration of sensors and monitoring systems in modern furnace roll designs allows for real-time performance tracking and predictive maintenance, further reducing the risk of unexpected failures and associated downtime.

Strategies for Maximizing Furnace Roll Lifespan

Proper Installation and Alignment

Ensuring proper installation and alignment of furnace rolls is crucial for maximizing their lifespan and minimizing downtime. Accurate alignment reduces uneven stress distribution and premature wear, contributing to smoother operation and extended service life. Experienced technicians should follow manufacturer guidelines and use precision tools to achieve optimal installation. Regular inspections and realignment procedures help maintain proper positioning throughout the rolls' operational life, preventing issues that could lead to unexpected failures or production interruptions.

Regular Maintenance and Inspection Protocols

Implementing comprehensive maintenance and inspection protocols is essential for preserving the performance and longevity of furnace rolls. Scheduled inspections allow for early detection of potential issues, such as surface wear, oxidation, or structural deformations. Proactive maintenance activities, including cleaning, lubrication, and minor repairs, can prevent small problems from escalating into major failures. By adhering to a structured maintenance program, manufacturers can significantly reduce the risk of unexpected downtime and extend the operational life of their furnace rolls.

Optimization of Operating Parameters

Careful management of operating parameters can substantially impact the lifespan and reliability of furnace rolls. Monitoring and controlling factors such as temperature gradients, load distribution, and rotation speeds help prevent excessive stress and wear on the rolls. Implementing advanced process control systems and thermal management techniques can optimize the performance of furnace rolls while minimizing thermal shock and fatigue. By fine-tuning these parameters based on specific application requirements and material characteristics, manufacturers can achieve a balance between productivity and equipment longevity.

Advanced Technologies Enhancing Furnace Roll Performance

Innovative Coating Technologies

The development of advanced coating technologies has significantly improved the performance and durability of furnace rolls. Ceramic and metallic coatings applied through techniques such as thermal spraying or chemical vapor deposition provide enhanced protection against oxidation, corrosion, and wear. These coatings can extend the service life of furnace rolls, reduce maintenance requirements, and improve overall process efficiency. Innovative multi-layer coating systems offer tailored properties to meet specific operational challenges, further contributing to minimized downtime and optimized production.

Predictive Maintenance Techniques

The integration of predictive maintenance techniques has revolutionized the management of furnace rolls in industrial settings. By employing sensors, data analytics, and machine learning algorithms, manufacturers can monitor the condition of furnace rolls in real-time and predict potential failures before they occur. This proactive approach allows for scheduled maintenance interventions, minimizing unexpected downtime and optimizing resource allocation. Predictive maintenance strategies enable more efficient planning of maintenance activities, reduced spare parts inventory, and improved overall equipment effectiveness.

Advancements in Materials Science

Ongoing advancements in materials science continue to push the boundaries of furnace roll performance and reliability. The development of novel alloys and composites with enhanced high-temperature properties offers new possibilities for extending the operational limits of furnace rolls. These advanced materials exhibit improved resistance to thermal cycling, oxidation, and mechanical stress, contributing to longer service life and reduced maintenance requirements. As materials science progresses, the integration of these innovative materials into furnace roll design and manufacturing processes will further enhance their ability to minimize production downtime.

In conclusion, furnace rolls play a critical role in minimizing production downtime across various industries. Their ability to withstand extreme temperatures and harsh environments while maintaining reliable performance is essential for continuous operations. By implementing proper maintenance strategies, leveraging advanced technologies, and utilizing high-quality materials, manufacturers can significantly reduce unscheduled downtime and optimize their production processes. As the demand for efficient and reliable manufacturing continues to grow, the importance of well-designed and properly maintained furnace rolls cannot be overstated. For more information on high-quality furnace rolls and how they can benefit your production processes, please contact us at info@welongpost.com.